Archive for Caravel project

August 2, 2008 at 9:04 pm · Filed under Caravel project, Home base

The Caravel project is done, at least for this summer. This morning we “struck the set,” as they say in show business. That means the shed we were working in has been completely cleared out. All of the tools are packed away in a box for next year, and the wood scraps have been hauled off for future bonfires by the beach. The only clue that we were working in the shed is some sawdust on the floor.

I drove all the old and new parts back over to Plattsburgh NY this morning and, with Colin Hyde’s help, loaded them carefully into the Caravel for future installation. This was the first opportunity I’d had to see how the stained wood complemented the Marmoleum floor. The effect, as I expected, is perfect — a testament to Susanne Brown’s ability to manage colors. We’ll be asking her for recommendations on fabrics and countertops as well.

It’s exciting to see all the parts in the Caravel, because it means that after almost four years of being on hold, the project is finally nearing completion. We had stopped work on the Caravel back in late 2004 when we began working on the 1977 Argosy project (“Vintage Thunder”), and then we went out to travel full-timing for “six months” in 2005. You know how that worked out. So until this summer, we’d never managed to get back to the poor old Caravel. There’s a very good chance we’ll have it ready to camp by the latter half of Summer 2009, which will be great fun.

We’re also striking the set on our Vermont visit. It has been fun, but two months is a good long visit and it is time to get moving again. I have to admit that I’m not going to miss the nearly-constant rain (another thunderstorm this evening washed out our celebratory “farewell” dinner). If it had rained less we would have spent more time on the boat, skiing, wakeboarding, fishing, and cruising. As it was, we spent much of the past two months watching weather radar on the computer and trying to figure out activities around the frequent downpours.

After a long stop like this, the preparations to leave are numerous. I’ve got to do a bunch of minor safety checks and maintenance items on the trailer, like lubing the hitch and topping off the tires, but that’s nothing that you wouldn’t do for any weekend trip. We also always take the opportunity to thoroughly re-pack and clean the trailer. We can clean on the road (and we do) but it’s more convenient to do it in someone’s driveway where we can borrow a powerful vacuum and other cleaning tools.

After a long stop like this, the preparations to leave are numerous. I’ve got to do a bunch of minor safety checks and maintenance items on the trailer, like lubing the hitch and topping off the tires, but that’s nothing that you wouldn’t do for any weekend trip. We also always take the opportunity to thoroughly re-pack and clean the trailer. We can clean on the road (and we do) but it’s more convenient to do it in someone’s driveway where we can borrow a powerful vacuum and other cleaning tools.

Eleanor began repacking food yesterday. I have no idea what she has loaded but I know we’ll be well stocked when we go. She’s also laundered everything that can be laundered. Today and tomorrow her major job will be to find all the items belonging to us that are scattered around the house, garage, beach, and yard, and put them where they belong — or decided that they need to be scuttled. I’ll be doing that as well, since this is a great opportunity to do one of my favorite things: cull down what we are carrying around.

We have left the 1983 Honda at Colin’s shop in Plattsburgh, right in front of our 1963 Serro Scotty and just a trailer away from the 1968 Caravel. The Honda has been put to bed for the season, with a full tank of fuel plus fuel stabilizer, and the battery stored inside the shop. I think it has been a success. Despite a couple of repairs, it has been a good set of wheels and carted us around about 2,000 miles this summer.

While we were in Plattsburgh, Colin took the opportunity to show us some of his recent projects. The photo above is of his “Airstream” canoe. Look carefully and you’ll see the vintage Airstream nameplate he bolted on it. The canoe was a green-colored $50 yard sale special with holes in it. A few weeks later Colin had it looking like new and ready for some trips in the Adirondacks. Seeing what he does with old “junk” is really inspiring to me.

This evening I realized that I could check my tire pressure while sitting at the dinette typing this blog. I just grabbed the Doran 360RV unit from the truck and plugged it into the 12v socket in the trailer. In a couple of minutes it will report the pressure of all four tires, so I’ll know if I need to plan some time to reinflate any of the tires (or deal with a possible slow leak) in the morning.

Oh look, it’s already reporting. One tire shows 59 psi, the other three are showing 60 psi. I like this method — this is the civilized way to check the tire pressure, especially when it’s raining! Those pressures are good news. It shows that none of our tires have a slow leak or any other problems that sometimes crop up when parked for a while. They’ve all lost a few pounds since I last aired them up in North Carolina (in May), but about one pound per month is considered normal. At 60 psi I don’t really need to add air. Our gross weight is light enough that 60 is just fine. But if the sun is shining in the morning I may top them up to 65 psi anyway.

We have decided not to rush off in the morning tomorrow. Instead, we’ll take our time getting out, probably departing in the early afternoon. Our first day will be a short one of about three hours drive time. After such a long time of being parked, it’s nice to have a soft start to get back into the travel mood.

August 1, 2008 at 6:23 pm · Filed under Caravel project

I bet you’ve never before seen anyone rebuild the furniture in an Airstream in five days.

To be fair, I haven’t completed everything. So far I’ve managed (with Eleanor’s help) to rebuild, stain, and partially finish the gaucho, galley, half the dinette, and a lot of miscellany. That includes nine doors and drawer fronts. Still to be done are two overhead storage lockers, the other half of the dinette seat, the table, a cover for the water tank, shelving, and one bulkhead. Work-wise, I would say about 70% of the job is done at this point, because the pieces of furniture I built are the really fussy ones.

Even though I’m not going to deliver a complete interior to Colin tomorrow, I am reasonably satisfied with what we accomplished. The guys in Plattsburgh will apply two more coats of polyurethane, since I barely had time to apply one coat. More importantly, enough of the critical components are done for the guys in Plattsburgh to complete the plumbing and install the appliances. Whatever is left can be dealt with by me next summer.

The stain mix came out very well. The wood still looks like ash, but it has a mellower tone and the grain has evened out. Looking at multiple pieces stacked together you can see that they cooperate visually, which is important in a small trailer. One of the things that annoyed me about the old furniture was that prior owners had substituted oak in some places, with a matching stain color. The result was a weird sort of clash, where the color pretended to be the same but the grain gave away the secret.

The stain mix came out very well. The wood still looks like ash, but it has a mellower tone and the grain has evened out. Looking at multiple pieces stacked together you can see that they cooperate visually, which is important in a small trailer. One of the things that annoyed me about the old furniture was that prior owners had substituted oak in some places, with a matching stain color. The result was a weird sort of clash, where the color pretended to be the same but the grain gave away the secret.

After putting away the leftover wood and storing the tools, I tallied up the expense of this project. The total is $999.54, of which the vast majority of expense was the wood ($770). I could have cut the costs further by selecting a less expensive wood, such as birch, and using luan for the shelves and interior partitions. But the final effect of the ash with the stain mixture and polyurethane is just great, and I am sure we will not regret the cost later.

In fact, I am already happy to think of the money I saved by doing it myself. Between Eleanor and myself we have about 60 hours in this project. Even allowing that a professional might have done it in 50% of the time, we easily saved $2,000 in labor charges. And of course, there’s that self-satisfaction that comes from enjoying your own handiwork.

I’m sure years from now when we are camping somewhere in our Caravel, I’ll have forgotten the tribulations of this project. I won’t remember the little tiny black bugs that kept landing on my freshly-stained pieces today, or the brutal humidity that put me into a dripping sweat at 72 degrees. I hope I don’t remember the moment I tipped over a bucket of stain on my feet. With luck, the interior of the Caravel will be what it is supposed to be: a peaceful retreat in which to enjoy camping and family, and make better memories than those.

Eleanor was not available to help me much today, but she did work on another construction project of sorts. She made a quilted bag designed specifically to house my new inkjet printer while it is stored in the closet. The bag gives the printer enough cushion so it won’t get scuffed in transit. It even has a Velcro flap across the top, so I can quickly deploy the printer and then slip it back into its case. It’s perfect.

We’re packing up to leave now. Our departure will be Sunday, and we expect to be on the road for at least two months, possibly three. Of course, with this week completely consumed by furniture work, I have a backlog of office work to do, so I expect a hectic week to come between driving and trying to catch up on work. Tomorrow will be the craziest day, since I need to somehow simultaneously get all this wood to Plattsburgh and get the Airstream ready for departure and deal with the business. Well, we got this far … I have to have faith that the rest will get done too.

July 31, 2008 at 5:16 pm · Filed under Caravel project

I’m nearing the end … I have to be.

I really didn’t anticipate spending this much time on this project. Today was another 8+ hour day, cut short by rain at 4:45 p.m. That puts the total of my hours up to about 30-35, and Eleanor has probably put in about 16 additional hours. Why am I surprised? It’s a big job, even for a short 17-foot trailer.

I soloed today. Eleanor wasn’t available for more than an hour due to things on her schedule. Fortunately at this point I’ve figured out how to set up large pieces for cutting by myself, so the need for someone to hold the end of the board was minimal. Despite working alone I managed to make pretty good progress: another closet door (a tricky job due to its length), a dinette end, a half-height bulkhead that goes next to the refrigerator, two sliding doors, two under-dinette doors, and several “mystery pieces.” That’s one of them in the photo, sitting next to the ratty old part it replaces.

I soloed today. Eleanor wasn’t available for more than an hour due to things on her schedule. Fortunately at this point I’ve figured out how to set up large pieces for cutting by myself, so the need for someone to hold the end of the board was minimal. Despite working alone I managed to make pretty good progress: another closet door (a tricky job due to its length), a dinette end, a half-height bulkhead that goes next to the refrigerator, two sliding doors, two under-dinette doors, and several “mystery pieces.” That’s one of them in the photo, sitting next to the ratty old part it replaces.

I’m really glad we are rebuilding the entire interior. After spending a pile of money to have every other part of the trailer renovated, it just didn’t seem right to put the old interior back. I was considering it for economy’s sake, but never really was enthusiastic about the idea. Now that I’m deep into the guts of our cabinetry, I can see the water stains from ancient leaks, burn marks from a plumber’s torch, multiple stripped-out screw holes, and even a little rot here and there. Even though some parts of the cabinetry (such as the interior partition at right) won’t be visible to visitors, the smell of decay and the occasional crumbling of wood would have bugged me forever.

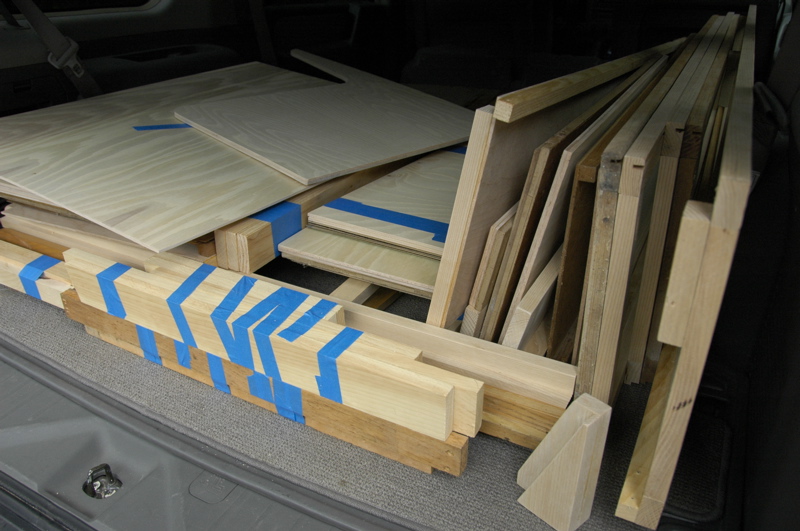

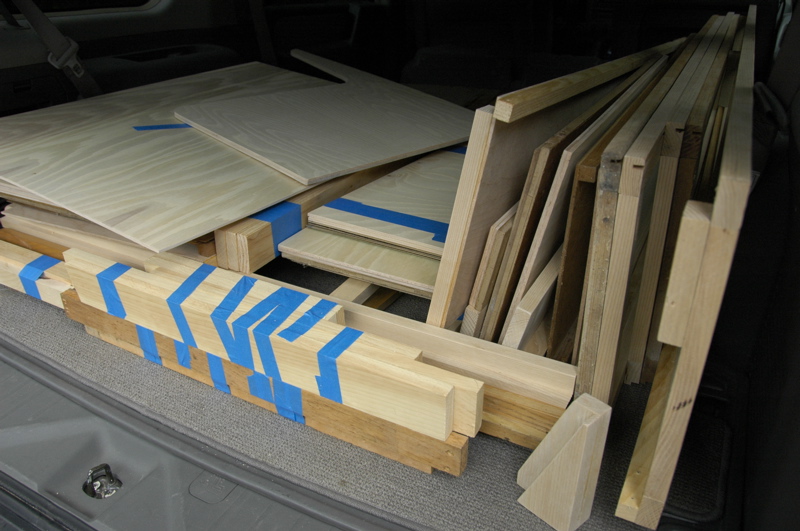

At this point almost every piece is done except the two overhead compartments, and a few pieces of the interior that didn’t make it back to here. I’m going to store the overhead compartments and the remaining plywood to re-build them, and bring all the completed parts to Plattsburgh for re-installation. As I write this, the final two glue-ups are setting on the workbench. In the photo you can also see a large bulkhead off to the right. Every other completed part is loaded in the Armada.

At this point almost every piece is done except the two overhead compartments, and a few pieces of the interior that didn’t make it back to here. I’m going to store the overhead compartments and the remaining plywood to re-build them, and bring all the completed parts to Plattsburgh for re-installation. As I write this, the final two glue-ups are setting on the workbench. In the photo you can also see a large bulkhead off to the right. Every other completed part is loaded in the Armada.

Susanne called this morning with five stain recommendations, three from Cabot and two from Minwax. Her suggestion was to match the background color in the Marmoleum floor, which is a sort of subtle putty color. The floor’s primary color is yellow, but if we matched that color the interior could get overwhelming. We picked up three of the Cabot colors and I applied them to some scraps, then sprayed them with polyurethane for get a finished look. One was ruled out right away (“Coastal Gray”), and the other two are in consideration.

I suspect we’ll go with the middle one, which is called “Cocoa Bean.” It accomplishes our goal of evening out the look of the wood, without overpowering the interior. The “Honeycomb” on the left is not bad but in real life it appears rather loud. My preference is for a warmer tone than the Cocoa Bean, but anything warmer might clash with the floor. Susanne is a professional Interior Designer and I’ve seen several of her interior designs in trailers, and they are always beautiful and understated. So I trust her. Eleanor will review the colors tonight and hopefully we’ll make a choice, so we can begin staining on Friday.

July 30, 2008 at 10:05 pm · Filed under Caravel project

Amazing! Another mostly sunny day. That’s practically a record lately, so we took full advantage and spent it all working on the Caravel’s furniture. The “shop” is humming right along, although we lost a lot of time today waiting for glue to set.

Although yesterday I said we weren’t able to use glue, what I meant was that we can’t use glue on pieces that will need disassembly for shipping purposes. There have been at least a dozen places where glue has been indispensable, especially building the cabinet and closet doors. We managed to finish all the doors we started yesterday, including final trim and sanding. They look great.

Our technique of stacking all the doors in a pile and then weighting the pile down with paving stones worked very well, so we’ve been doing that all day instead of using clamps. With limited flat clean space to work on, the table in the Airstream had to be pressed into service too. That helped keep up the pace of production at our “furniture factory” (as my father calls it).

We also finalized the gaucho, then disassembled it and packed it in the Armada with the rest of the rapidly-growing pile of furniture. In between large cuts, I put together some of the many “miscellaneous” pieces, including two interior partitions for the kitchen, one interior partition for the gaucho, some blocks, and a couple of facias. There are still another half dozen or so miscellaneous pieces yet to go.

Eleanor tested the stain we bought, but it was a disappointment. We don’t have time to keep experimenting with stain, so I called Susanne Brown, the interior design expert and asked her to recommend a stain that would work with the color of Marmoleum floor we have. She’s working on it. Stain may become the bottleneck of this project, since we can’t put polyurethane on anything until we have the stain picked out and applied.

We aren’t going to build any of the interior shelving at this point. All of the shelving has been replaced by prior owners and no two pieces are the same. Instead, we’ll build shelving after everything else is installed, next summer. That will allow us to customize the interiors of the cabinets and closets to suit our needs.

A big pleasure of doing this project comes from being able to replace the old parts with new parts that are much better than the originals. I can take a little extra time and re-design a piece to have a nicer curve, fewer screws, smoother edges, tighter joints, or stronger supports. For me, that is a big reward and a motivator. Our trailer will be better than new, when we’re done.

One of the problems we are facing at the moment are the “mystery” pieces. We have an entire box of oddly-shaped wood parts that we can’t identify. They are so strangely designed and unfamiliar that it is hard to believe that they even came out of our trailer. Some of them are clearly shelves, which means we can ignore them, but others have pieces of finished elm on them, which means that they are visible somewhere in the trailer. We can’t ignore those.

The problem with those pieces is that in most cases they have obviously been re-worked by someone. That’s generally a bad thing, because re-worked parts tend to be — shall we say — “less than optimal.” They are shabby, riddled with mismatched screws, and have the distinct appearance of having been “fixed” in a big hurry.

If I knew what those parts were, I would know whether we should re-build them exactly as they appear, or design them more suitably for their function. But we are so far flummoxed by about ten strange parts. If I spend time rebuilding them and they turn out to be messed-up designs, that’s a lot of valuable time and wood wasted. Tomorrow I have to start on them if they are to get done at all, so some rapid decision-making will be done in the morning when I’ve got a fresh mind to consider the problem.

This is the first woodworking project I’ve taken on since we sold our house three years ago. As Eleanor and I worked on it today, little tricks I’d forgotten kept popping back into my mind. I remembered how to straighten a crooked board on the tablesaw, how to set up a straight line cut with a jigsaw, and a thousand other small tips that sped the work. I also popped the iPod into our new Atlantic Ego sound case, so we had tunes all day long too. (The nice thing about the Ego case is that it is dustproof and waterproof. It gets covered in sawdust, but at the end of the day I just rinse it off in the sink!)

Between motivation, memory, and music, the work moved along quickly. Now I’m starting to regret the impending end of this phase of the project. I’d like to keep going, and install all our handiwork in the Caravel right away. But with only a handful of days left, that’s impossible. We’ll put in just another day or two, before we hit the road again.

July 29, 2008 at 8:18 pm · Filed under Caravel project

We are making progress rebuilding the Caravel’s furniture. Today, being the only day this week without thunderstorms in the forecast, Eleanor and I decided to clear the decks of all other obligations and work exclusively on the Caravel project. I started around 8:30 a.m. and Eleanor joined me at 10, and we worked steadily through the day until 5:30 p.m.

We managed to complete the other closet door, most of the gaucho, most of the major plywood pieces, and we rough cut most of the doors and drawer fronts. As we finish parts, they get stacked up in the Armada with the old parts for reference. (At right, old and new closet door frames.)

We managed to complete the other closet door, most of the gaucho, most of the major plywood pieces, and we rough cut most of the doors and drawer fronts. As we finish parts, they get stacked up in the Armada with the old parts for reference. (At right, old and new closet door frames.)

It’s encouraging that much progress has been made, but discouraging to see how much there is left to do. The entire morning was spent building the gaucho. This turned out to be the most challenging piece so far, because the gaucho has been hacked up by at least three previous owners. Only about half of its structure was original; the rest was a mish-mash of do-it-yourself “repairs”.

A fun part of this project has been studying how the furniture was built by the unnamed craftsmen in Jackson Center, Ohio, back in 1968. It’s not complicated, but it is mildly impressive by virtue of its simplicity, functionality, and light weight. The entire gaucho frame is about ten pounds. The frame was trimmed to a bare skeleton, but despite its parsimony it has managed to last for forty years in regular use.

At the time that our Caravel was built, Airstream had been making trailers for about 33 years (minus a hiatus caused by World War II). I suppose it’s not very surprising that they had figured out how to do it well by 1968. Even in the 1950s, when Wally Byam was still alive, he would harp on the furniture makers to trim ounces (“Ounces make pounds”) and make use of every inch of space.

With the gaucho in our trailer, however, a bevy of hacked modifications layered upon previous repairs resulted in a very confusing mix of construction styles. Each of three structural legs of the gaucho was constructed differently. One appeared to be original but had a giant L-bracket screwed onto it. Another seemed to have been stripped down and pieces were missing. The third was augmented by a horrible heavy subframe made of 3/4″ plywood.

We also added some challenges to the project, as a result of our joinery choices. The original design relied heavily on staples, which we don’t want to use if we can help it. No staples or glue can be used because we need to disassemble many of the parts for shipment. We’re using screws, which means some design modifications to the internal frames. So far we’ve used over 100 screws, each one hidden from view. We’re also taking the time to countersink every screw.

With the challenge of forensic study added to the task of building the thing, it ended up taking several hours of the day. We built about 90% of it, then set it aside to start cutting plywood. Tomorrow we’ll complete it, and then break it down to a set of four flat pieces plus connecting boards. Even unfinished, I have to say that it is a huge improvement over what was there. I’m fairly pleased at the results.

The budget has continued to rise. We’re up to about $900 so far, including everything. The “general purpose” blade in my table saw was not up to the task of making clean cuts in 1/4″ veneer plywood, so Eleanor and I went to the hardware store last night to get a better one. We also got some specialized blades for the jigsaw, a couple of additional pieces of pine, and some stain. We’ve decided that the look of the ash is a bit too “raw”, and are looking for some way to even out the appearance of it. We’ll do some stain tests shortly, to see if we can find one that gives it a nice mellow tone without getting too red or yellow.

With the new blades in place, plywood cutting was fairly quick, but selecting each piece prior to cutting took some time. We cut a major bulkhead (wall), five doors, one dinette end, and one large interior partion for the gaucho. This took a bit of time just because of the task of wrestling 4×8 sheets of plywood, but also because each door requires two separate pieces. The doors need to be 1/2″ thick, whereas bulkheads and interior partitions are 1/4″ thick. Rather than buy 1/2″ and 1/4″ plywood and have more waste, we chose to duplicate what Wally’s guys did, and glue two 1/4″ sheets together to make the doors.

With the new blades in place, plywood cutting was fairly quick, but selecting each piece prior to cutting took some time. We cut a major bulkhead (wall), five doors, one dinette end, and one large interior partion for the gaucho. This took a bit of time just because of the task of wrestling 4×8 sheets of plywood, but also because each door requires two separate pieces. The doors need to be 1/2″ thick, whereas bulkheads and interior partitions are 1/4″ thick. Rather than buy 1/2″ and 1/4″ plywood and have more waste, we chose to duplicate what Wally’s guys did, and glue two 1/4″ sheets together to make the doors.

To complicate things, we decided to save money by using ash on the outside, and birch on the inside. The birch was about half the cost of the ash plywood. Each sheet has an “A” side with the best appearance, and a “B” side that gets glued. So for asymmetrical parts like the dinette end, we have to be careful to select properly oriented pieces that look good and make good use of the sheet. Even doors are a small challenge, because we need to orient the grain of the wood properly and avoid bad spots in the plywood. Once we’ve selected the section of wood we’re using, we rough cut them with the jigsaw or tablesaw about 1/2″ oversize, glue them together, and trim to finished size after the glue is set.

Since we don’t have enough clamps for all the pieces we are gluing tonight, we just slathered the pieces with glue, stacked them on the workbench, and piled heavy paving stones on top. Hopefully this will give us a nice even attachment between the birch and ash pieces. We’ll find out tomorrow when we come back to trim them all to final size.

Since we don’t have enough clamps for all the pieces we are gluing tonight, we just slathered the pieces with glue, stacked them on the workbench, and piled heavy paving stones on top. Hopefully this will give us a nice even attachment between the birch and ash pieces. We’ll find out tomorrow when we come back to trim them all to final size.

After a long day like this it’s hard to have perspective. It seems like we have more work left to do than we started with this morning. But when I tally it up, we’re actually doing quite well. Whether we finish by Friday is an open question right now, but if the weather is cooperative I think we just might.

July 27, 2008 at 8:35 pm · Filed under Caravel project, Home base

At long last Eleanor and I have found time to work on rebuilding the furniture for our 1968 Airstream Caravel. It’s awfully late to be starting this project, in the home stretch of our visit, but it’s now or never. All of the wood has been stacked in the shed for weeks, along with glue, fasteners, sandpaper, polyurethane, and all the tools we need. Our excuses for getting started this late are simply that we’ve been ridiculously busy on other things, and the relentless rain. But excuses don’t get the job done, and now the pressure is on.

A thunderstorm passes over Lake Champlain

On Saturday we got a break in the weather for half a day, so we got started on the project. Each piece of furniture in the trailer is to be recreated in new ash wood, duplicating almost exactly the original elm wood. With a light oak stain, the finished product would be nearly identical to the original in grain and color, but at this point I am leaning toward finishing with no stain, thus lightening the wood considerably from the original honey color. It should go better with the yellow/tan Marmoleum floor that is already installed in the trailer.

Our workshop is a 20×10 tent structure with a blue tarp floor. The ground is sloped to one end, enough so that a loose pencil will roll off the table. Tomorrow I will have to try to level it up a bit more, but so far we’ve just dealt with it as-is. Rainwater leaks around the perimeter and pools on the edges of the tarp, so any good wood has to be kept off the ground to avoid water staining. The tent is infested with spiders, Daddy Long-legs, and flying insects of every description, so much that each piece of wood must be brushed clean of insect legs and wings before use. As a result of the rain-saturated ground, it is intensely humid in there, even with the door wide open. In short, it is far from an ideal wood shop, but it’s all we have.

Our workshop is a 20×10 tent structure with a blue tarp floor. The ground is sloped to one end, enough so that a loose pencil will roll off the table. Tomorrow I will have to try to level it up a bit more, but so far we’ve just dealt with it as-is. Rainwater leaks around the perimeter and pools on the edges of the tarp, so any good wood has to be kept off the ground to avoid water staining. The tent is infested with spiders, Daddy Long-legs, and flying insects of every description, so much that each piece of wood must be brushed clean of insect legs and wings before use. As a result of the rain-saturated ground, it is intensely humid in there, even with the door wide open. In short, it is far from an ideal wood shop, but it’s all we have.

Getting started on a big project is always the hardest part. I did the first couple of hours alone, to get a sense of the process and the specific challenges. Then Eleanor joined in. Once we got past the first hour and both of us began to understand what we were doing, we began ticking along pretty nicely. She is specializing in drilling the joinery holes using the mini-Kreg, which involves careful clamping and adjusting. I mostly cut pieces to length and sand them smooth. Together, we manage the long rip cuts on the tablesaw and assemble the finished pieces.

Getting started on a big project is always the hardest part. I did the first couple of hours alone, to get a sense of the process and the specific challenges. Then Eleanor joined in. Once we got past the first hour and both of us began to understand what we were doing, we began ticking along pretty nicely. She is specializing in drilling the joinery holes using the mini-Kreg, which involves careful clamping and adjusting. I mostly cut pieces to length and sand them smooth. Together, we manage the long rip cuts on the tablesaw and assemble the finished pieces.

The only really safe dry storage we have is in the Armada, so all finished pieces are going in there, with loose parts taped and the original pieces alongside for reference during re-assembly. We can’t fully assemble the furniture, because it has to go back to Plattsburgh in a compact format, so we’re assembling all the flat sections and labeling how they go together.

The only really safe dry storage we have is in the Armada, so all finished pieces are going in there, with loose parts taped and the original pieces alongside for reference during re-assembly. We can’t fully assemble the furniture, because it has to go back to Plattsburgh in a compact format, so we’re assembling all the flat sections and labeling how they go together.

Today we put in another four hours before the heat of the day arrived. Progress has been reasonable. So far we have built the face frames for two closets, one side of the dinette, and the kitchen. We’ve still got another dinette side and the gaucho to go, plus two overhead cabinets, six cabinet doors, and a few simple bulkheads.

Whether we finish before we leave depends mostly on the weather. I’ve cleared some time in my work schedule this week, but if the thunderstorms continue it may not matter. I can’t use the tablesaw or chop saw when it’s raining (since they have to be set up outside the tent). In any case I’m not wild about building furniture in such humidity, since dry winter air will almost surely cause joints to open up. If conditions are really adverse, we can at least take some of the plywood down to the basement and start cutting it to shape with the jigsaw.

This weekend we’ve been visited by several friends from far away. Yesterday Abe and Melissa dropped by, visiting from Virginia. We just saw them a couple of weeks ago at the Vintage Trailer Jam, but they needed to come up to Vermont this weekend for somebody’s wedding so they popped by the house for a few minutes. Abe scored big points by bringing me a dozen maple donuts from a bakery in Waitsfield VT. He knows how to make himself welcome.

Today we had a sort of open house/beach party and invited several friends over. Among the guests were Felix and Patricia (with toddler Nicholas), who were the unnamed friends in a previous post from Tucson. Felix and I went to the same grade school in Vermont, and were by happenstance reunited last summer while we were both back in Vermont visiting. It turns out that he and Patricia now live in southern Arizona not far from our place, so we meet up at both ends of the country from time to time.

Splitting the time between work and fun is the only way to go. The Caravel project has the potential to be a nightmarish thing, but it should be a pleasant exercise if we handle it right. I actually do enjoy building things when I have time, and in the end there will be a lot of pride in having done it ourselves (and well), so if it comes down to rushing madly to complete the job or leaving it unfinished for next summer, we will leave it unfinished. At this point my goal is to get all the frames done, cut all the plywood pieces (so as to reduce them to manageable size), and deliver it to Colin up in Plattsburgh for winter storage. Finishing with polyurethane, hardware, final assembly, and fitting can be next summer’s project.

June 22, 2008 at 9:45 pm · Filed under Caravel project, Home base

It seems that every summer we are here in Vermont I end up writing about thunderstorms. I am sorry to be so repetitive, but the storms have always been the dominating influence on our lifestyle while we are here. We are slaves to the weather here in the northeast, with our daily activities determined in a large part by whether we will have snow, rain, or heat and humidity. Only rarely does it seem to be sunny and dry.

Back in Tucson our neighbors and friends are awaiting the annual “monsoon season.” Yes, the American southwest desert has a monsoon season, extending from June 15 to September 15, during which time the dew point soars up above 54 degrees and dramatic lightning storms roll in from the west and south. The dry washes are flooded with raging brown water, and in a couple of months Tucson receives half of the 12 or so inches or rain it gets per year.

Back in here in Vermont, we don’t have a monsoon season, because there is no season in which we don’t get thunderstorms and heavy precipitation. Or to put it another way, it’s monsoon season all year long.

As I write this I am sitting in the Airstream listening to today’s thunderstorm. It started with a sudden chill breeze at 8 p.m., dropping the air from 70 degrees to the mid-60s, and then long crackling distant warnings, that morph into a rumble and ten seconds of echoes and aftershocks. Then the rain began in earnest, rattling down on the aluminum roof and accompanied by huge booms that shook the Airstream. Eleanor and Emma are in the house right now, probably watching the storm through the glass sliders on the west side. I am comfortable and well-protected in here.

Our friends in Tucson told us we should be there for the monsoon season, and I’m sure it is a spectacular sight. In some future year we will be there to watch the blue storms gallop in from the west over the desert landscape. But for now we have the Vermont version, which I suspect is no less dramatic in its own way.

It wasn’t all storm today, however. After a solid week of on-again, off-again rain and sun, we got half a decent day, and that was enough to encourage my brother to come over with his sailboat. He and my parents jointly have purchased a 1975 Chrysler Buccaneer, an 18-footer that looks like serious fun to race around the lake. The boat needs a little work (new hatch covers mostly), but it should be sailable almost immediately. We spent an hour trimming trees with the chainsaw yesterday so that the Armada and boat could squeeze around the side of the garage to the lakeside, and today Steve trucked it over. The boat was dismantled for travel, so re-assembly work started this afternoon. If things go well, we could be sailing later this week.

I am told that Emma was the driving reason for getting this sailboat. Being the only grandchild, she’s a handy excuse for all sorts of things. But I heartily approve. Sailing is a good thing for a kid to learn, and a great outdoor activity for everyone. Emma has a book on sailing to study this week, so she’ll be ready for her first lessons.

My Caravel project is still moving along slowly. I was having trouble matching the wood in the trailer, so I brought a big chunk of it up to the wood experts in Burlington, and they determined that it is not oak (as many people have claimed), but in fact pecan. I am not entirely sure that is correct, but I do agree it’s not oak. The grain is all wrong for oak. It’s also not poplar, ash, or birch — all species which people have guessed at in the past.

Even if we were sure it was pecan, it would be tough to match new pieces to the old. Pecan isn’t as cheap as it was in 1968, either. So, after considering several options, I have decided to rebuild everything from new wood. This greatly increases the magnitude of the work, and the cost, but I am sure that the end result will be far superior. It will eliminate a lot of refinishing work and allow me to correct a few design problems as well.

For example, the kitchen cabinet front was built to accommodate a gravity furnace that is long since gone, and a fully manual Dometic gas refrigerator that (despite much work) still insists on freezing our lettuce. We will re-design the kitchen cabinets to allow a slightly larger and considerably better replacement refrigerator, and put in door fronts that reflect how we really use the space.

At this point we are looking at ash for the replacement wood. Ash has a light blonde color that will go well with the vinyl walls and warm yellow Marmoleum floor in the trailer. I’m awaiting a estimate on availability from our wood suppliers before settling on the wood choice. In the meantime, I’ve measured every piece of 1/4″ plywood and all the structural members of every cabinet in the trailer, in order to estimate our needs. It’s considerable: at least four sheets of veneer plywood, and many board-feet of 3/4″ lumber.

To speed the project, I’m asking the wood guys to deliver some stock pre-ripped to the dimensions we will need. They can do it more quickly and straighter than I can on my homeowner table saw. Most of the Caravel’s furniture was assembled from 3/4″ x 3/4″ or 3/4″ x 1-1/2″ sticks, glued and doweled, with 1/4″ plywood forming the sides, and two thicknesses of 1/4″ plywood glued together to make the cabinet doors and drawer fronts. I’m going to use pocket hole joinery using a Mini-Kreg kit with glue, instead of dowels. With a few improvements to the design, we will even save a few pounds, making the 2400-lb Caravel even lighter and easier to tow.

But that’s all just details. The best things that happened today were Emma playing a Hawaiian tune on her Flea “pineapple” ukulele for everyone, and Eleanor making a superb dinner of fresh Thai summer rolls with peanut dipping sauce, and shrimp on the barbecue. The little things are what make a summer’s day. The big projects are just the things we do to fill in the time between moments like those.

Next entries »

After a long stop like this, the preparations to leave are numerous. I’ve got to do a bunch of minor safety checks and maintenance items on the trailer, like lubing the hitch and topping off the tires, but that’s nothing that you wouldn’t do for any weekend trip. We also always take the opportunity to thoroughly re-pack and clean the trailer. We can clean on the road (and we do) but it’s more convenient to do it in someone’s driveway where we can borrow a powerful vacuum and other cleaning tools.

After a long stop like this, the preparations to leave are numerous. I’ve got to do a bunch of minor safety checks and maintenance items on the trailer, like lubing the hitch and topping off the tires, but that’s nothing that you wouldn’t do for any weekend trip. We also always take the opportunity to thoroughly re-pack and clean the trailer. We can clean on the road (and we do) but it’s more convenient to do it in someone’s driveway where we can borrow a powerful vacuum and other cleaning tools.